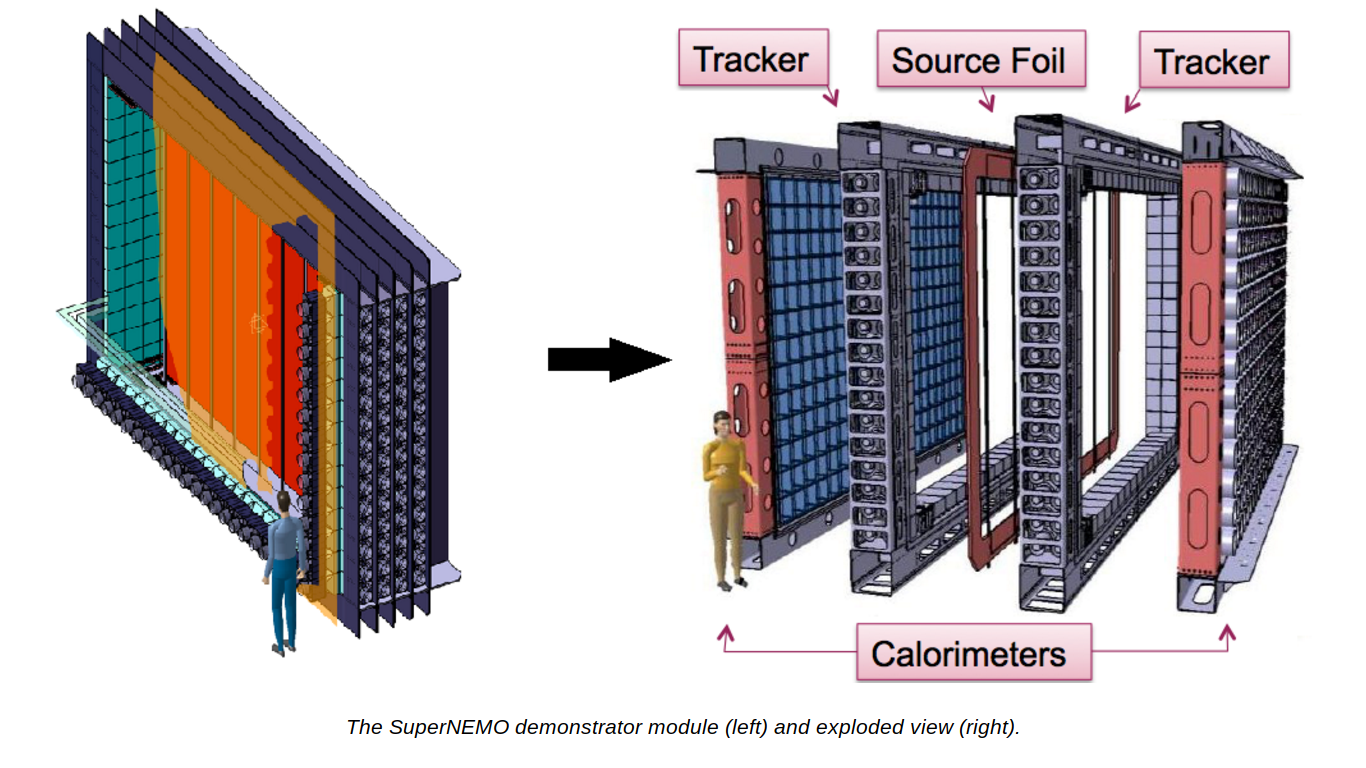

SuperNEMO

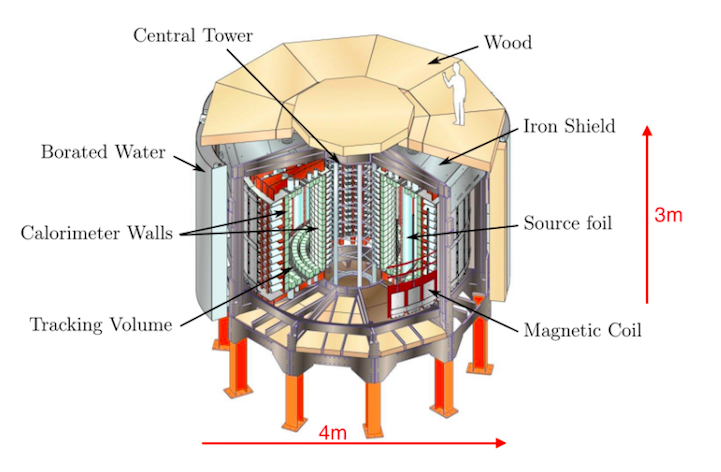

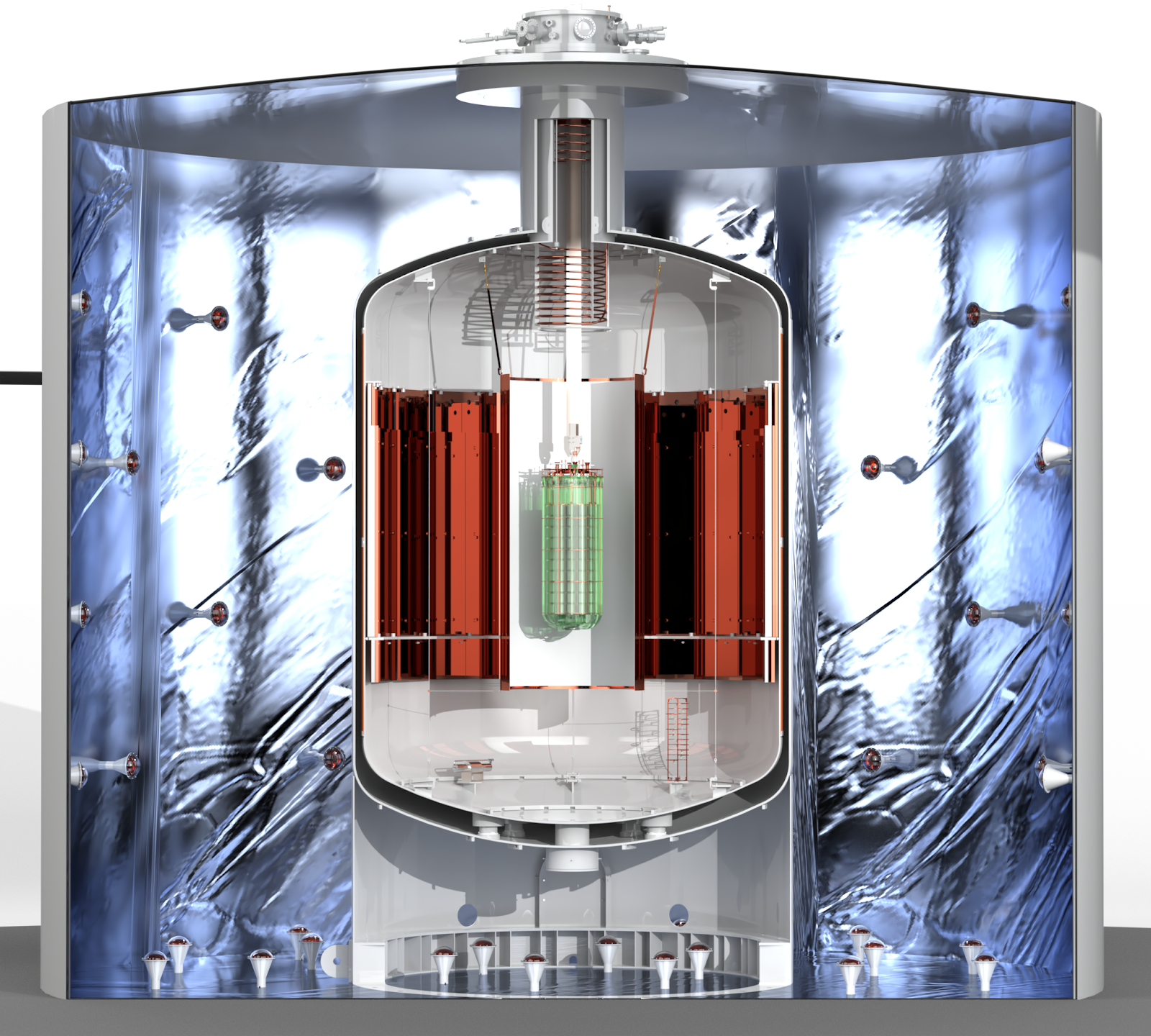

The success of NEMO-3 motivated an effort to construct a

new and better detector called SuperNEMO. It is designed to have larger

amounts of double beta decay sources and to be made out of materials

which are less radioactive than the ones used to build NEMO-3, further

reducing the possible background. SuperNEMO will also be composed of 20

modules. Approximately 5-7 kg of double beta decay isotopes will be

installed in each module, allowing it to have at least 10 times more

source mass than its predecessor. The materials to build the modules

were chosen so that, once built, each module will be less radioactive

than 8 bananas.

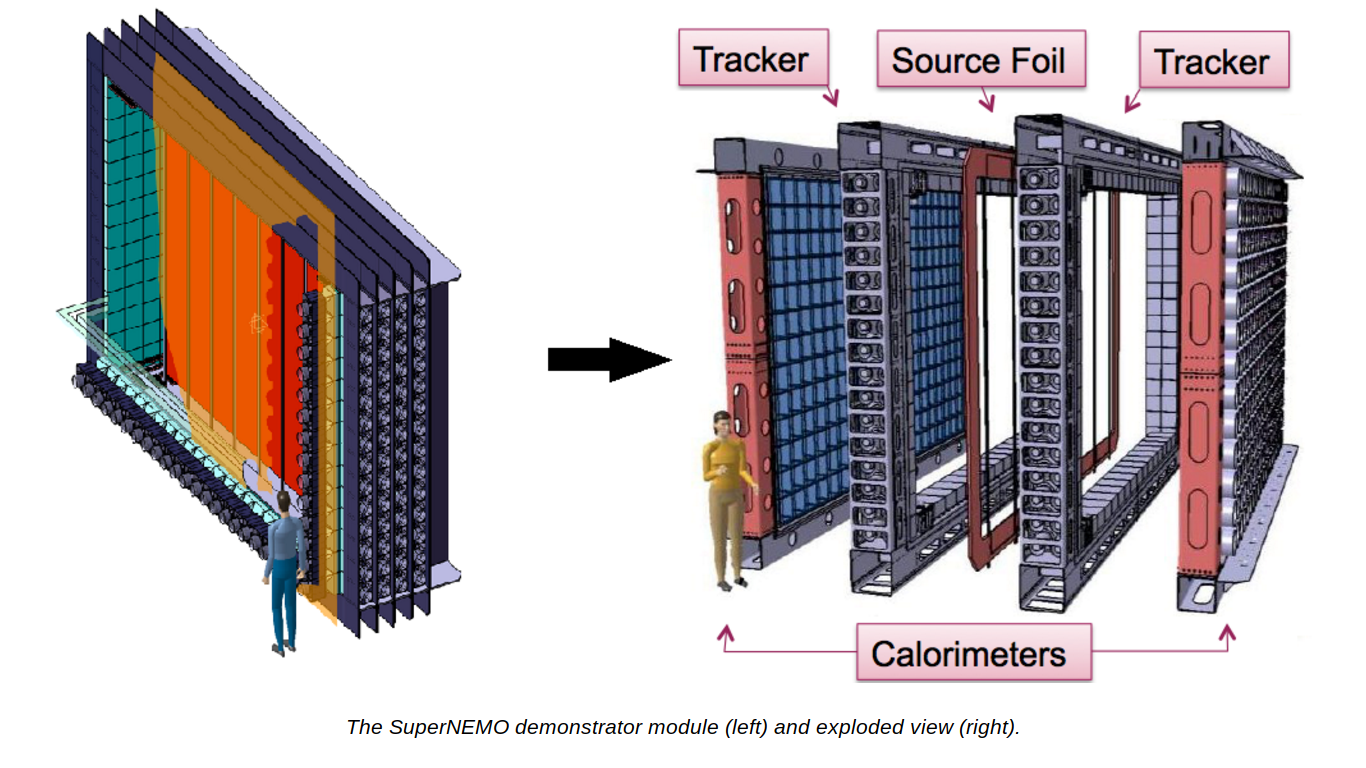

In contrast to the cylindrical shape of the NEMO-3

detector, the SuperNEMO modules exhibit a rectangular geometry. This

allows for a staged approach to the construction of the detector,

meaning that a module can be taking data while the rest of the modules

are being built. It also makes it possible to build this kind of modules

in other underground locations if desired. Lastly, this geometry

facilitates the extrapolation of sensitivity and performance from a

single module to the whole SuperNEMO detector.

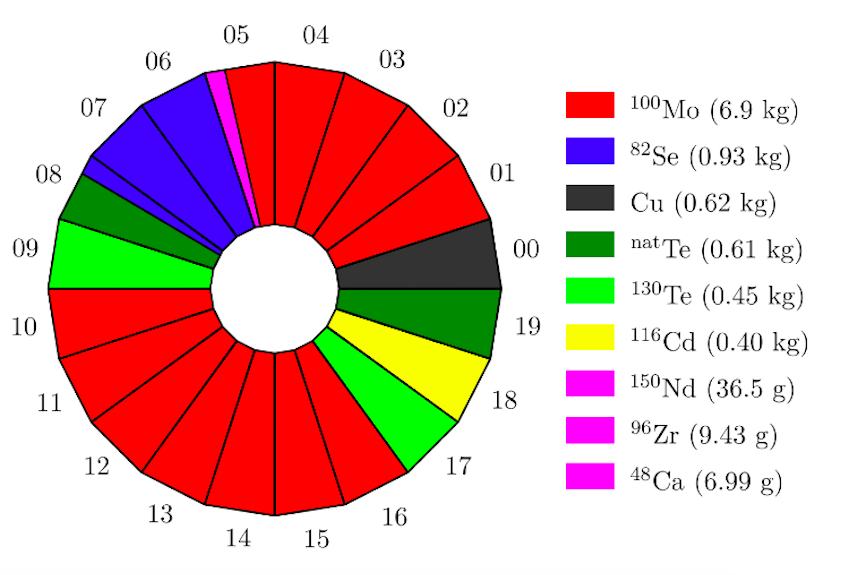

The first module, called the demonstrator, is currently under construction. It will be populated with 82Se

as its only source of double beta decays. However, since virtually any

double beta decay source may be used, the possibility of enriching and

using 150Nd and 48Ca is being investigated. The SuperNEMO experiment is aiming to reach a sensitivity greater than 1026 years for the half life of neutrinoless double beta decay, which translates to an effective neutrino mass of 50-100 meV.

Our group’s involvement with this experiment consists of

two calibration systems: The Calibration Source Deployment System, and

the Light Injection System. Information about each of them can be found

in the following links:

Radioactive Source Deployment System

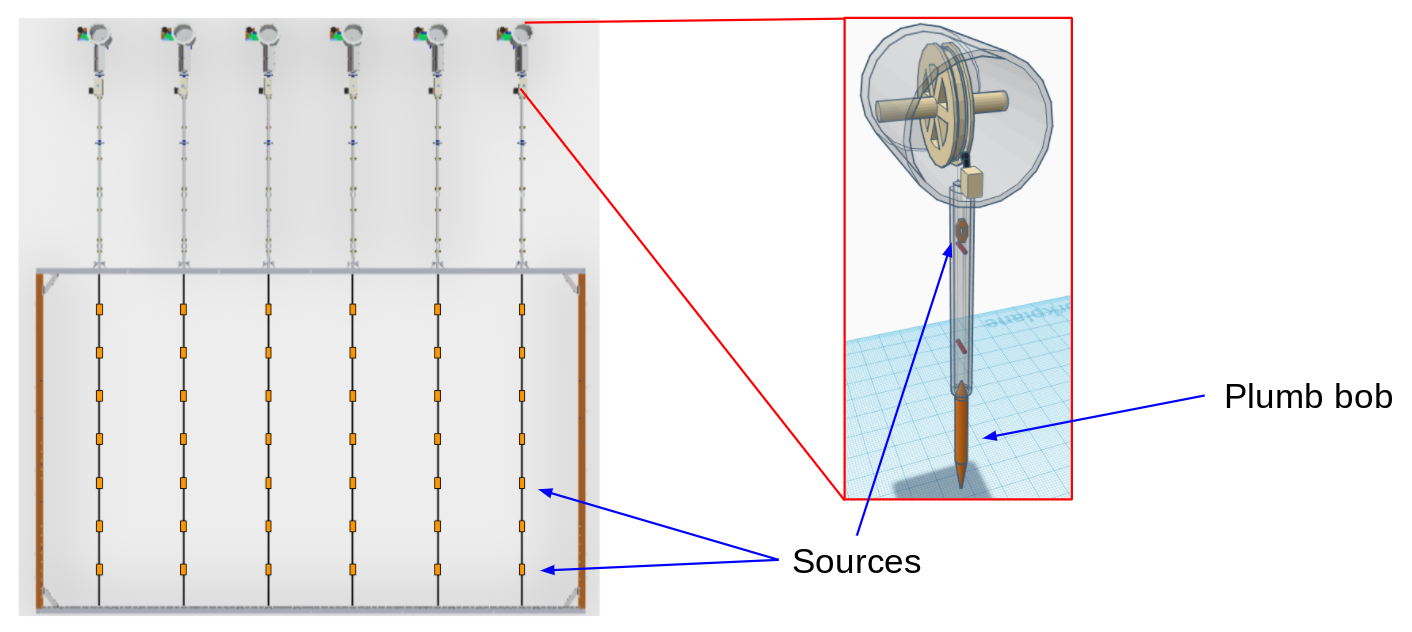

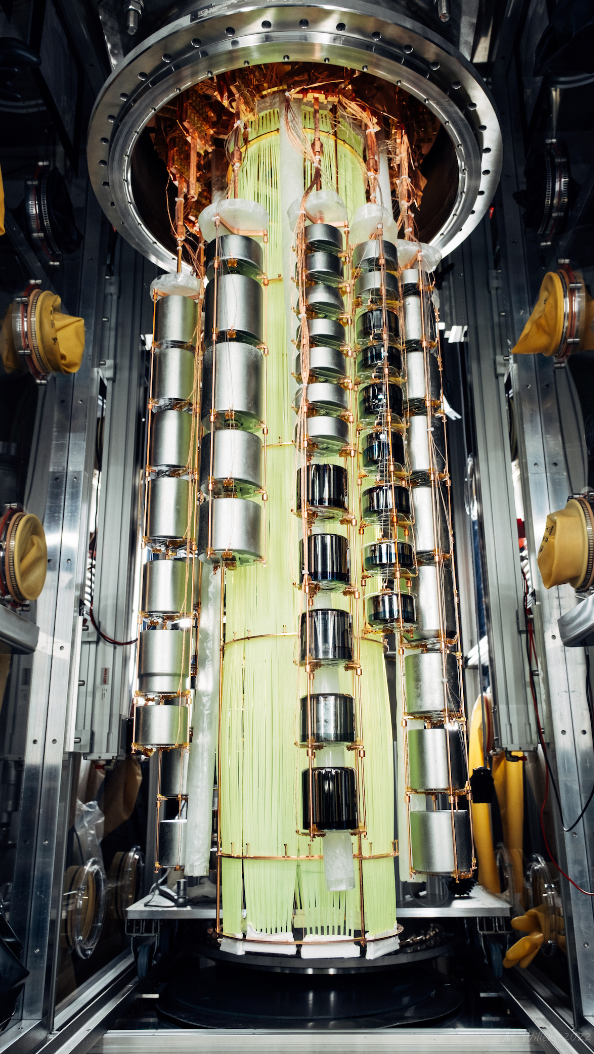

The radioactive source deployment system consists of six

oxygen-free copper plumb bobs suspended from stainless steel wires

inside the SuperNEMO source frame. Each wire is wrapped around a wheel

on top of the detector (housed inside a stainless steel vessel) which

may be rotated by a stepper motor, lowering and raising each plumb bob.

At seven fixed positions on each wire above the plumb bobs, 207Bi

calibration sources are attached, making it possible to introduce the

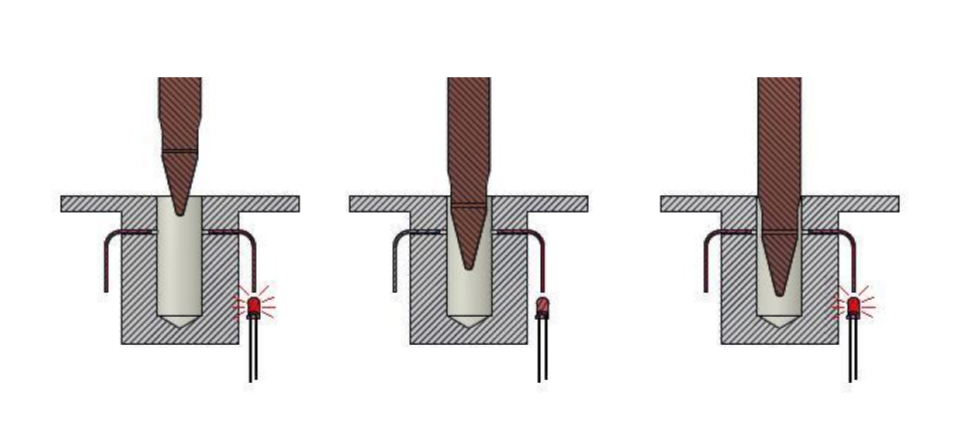

sources into the detector. At the bottom of the source frame there are

six nests with laser light passing through them. Each plumb bob has a

hole big enough for the laser beam to pass through. As a plumb bob

enters a nest, it first interrupts the laser; this interruption is

detected by a computer which slows down the motor. As the plumb bob

continues descending, it reaches a position where its hole aligns with

the laser beam. The computer is once again alerted by this change, and

it stops the motor completely.

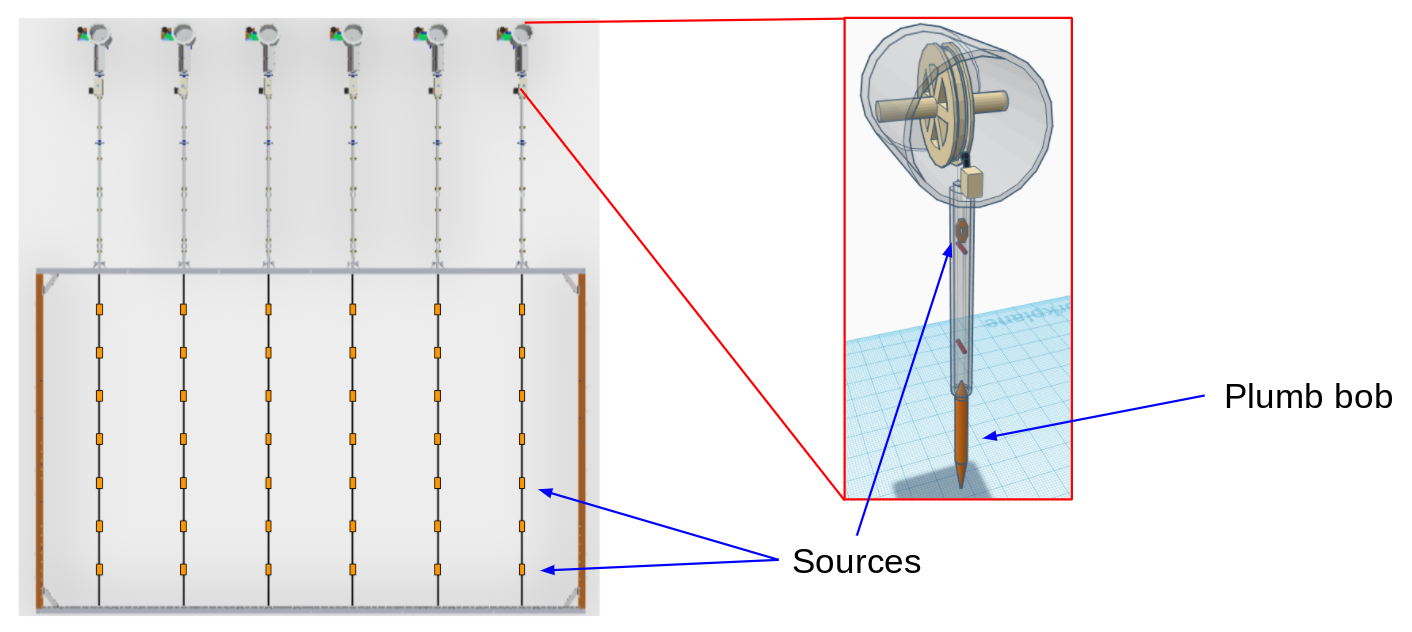

Left: The six different calibration lines installed on top of the

SuperNEMO source frame. Right: A close up of one of the vessels which

houses the wheels which raise and lower the plumb bobs and calibration

sources.

The system is fully automated. Photodiode amplifiers are used

to create electrical signals whenever they receive light from the

lasers. These signals are the way the computer knows when the lasers are

interrupted and uninterrupted. The computer which controls the whole

system, called CompactRIO, communicates with the stepper motor drivers

which actuate the stepper motors that deploy the plumb bobs. The

CompactRIO has 64 inputs/outputs, and it uses LabVIEW as the language

that interprets and analyzes the inputs to decide which outputs need

to be sent.

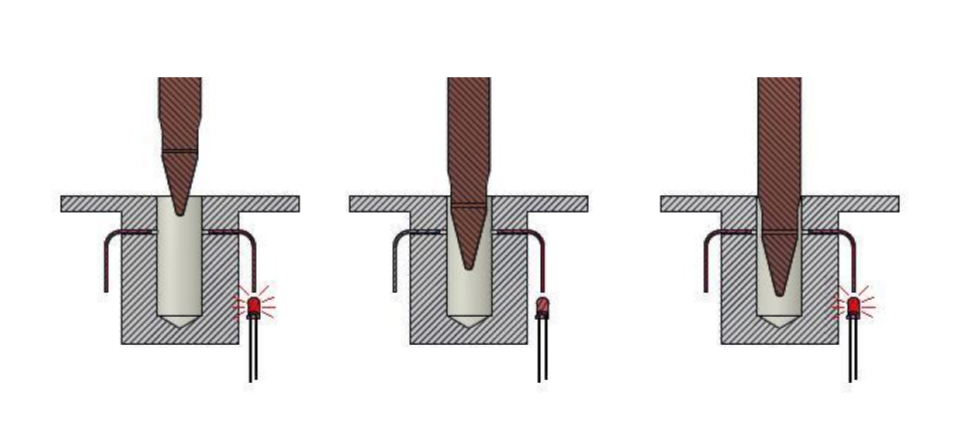

Computer drawings showing how a plumb bob interacts with the light

passing through a bottom nest in order to find its lowest position.

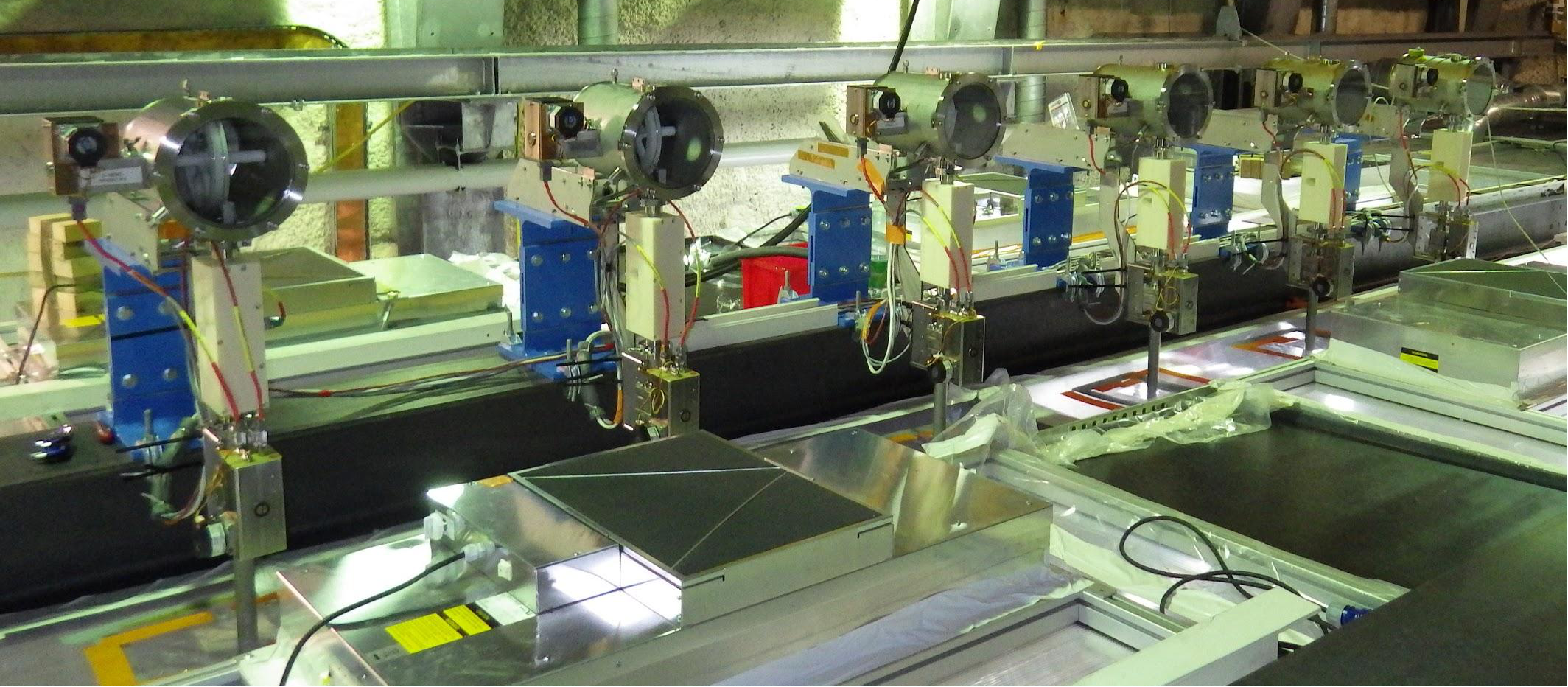

The radioactive source deployment system has already been installed and

incorporated into the SuperNEMO detector. The mechanics of it

(introduction and retrieval of the calibration sources) have already

been successfully tested, and it will begin performing calibration runs

some time in the year 2021.

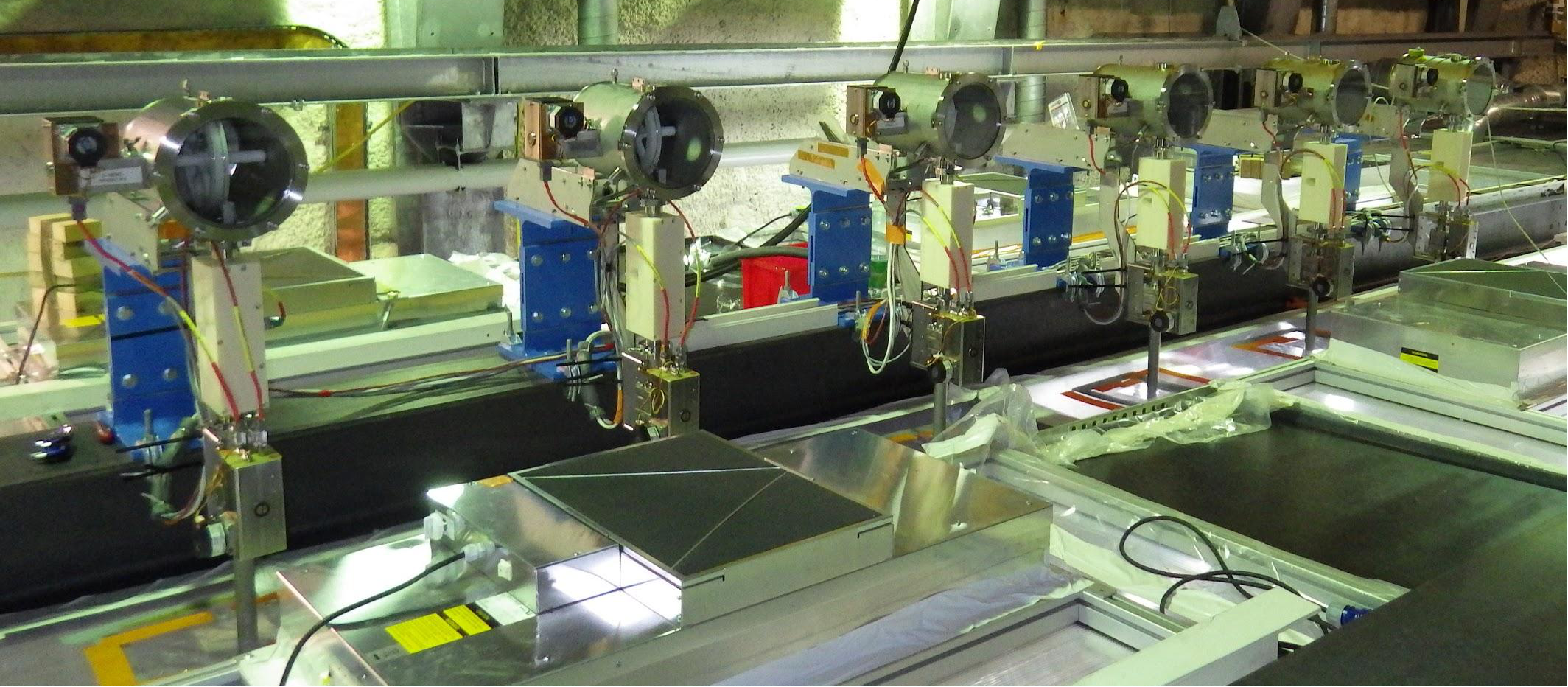

Vessels mounted on top of the SuperNEMO detector.

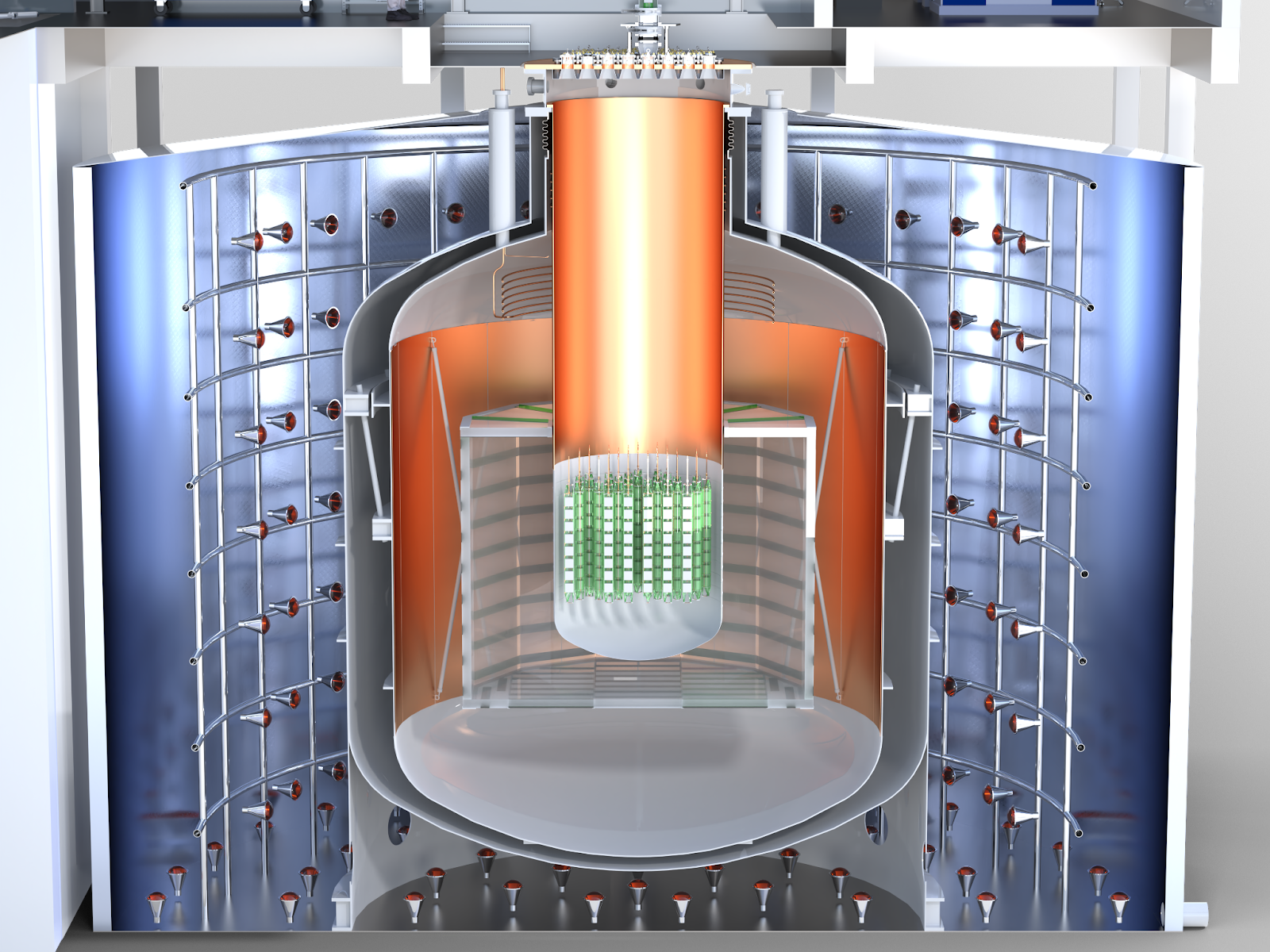

Light Injection and Monitoring System

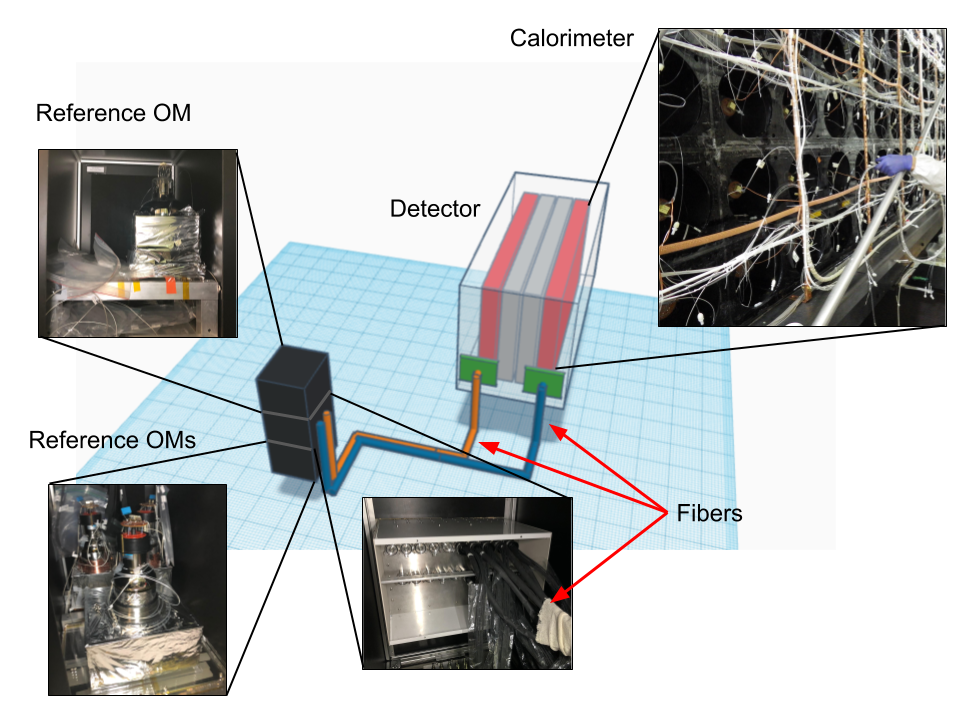

The

Light Injection and Monitoring (LIM) System injects pulsed UV light

into each optical module of the SuperNEMO calorimeter via optical fibers

to control and monitor their energy response over time. The aim of the

LIM system is to guarantee the stability of the calorimetric response to

within 1%. The LIM system consists of 20 UV-LEDs illuminating ~1500

optical fibers routed to optical modules. Each LED illuminates a bundle

of ~75 fibers. Reference optical modules outside the detector are used

to monitor the energy of 207 Bi sources as well as the light levels of

some optical fibers connected to each of the 20 UV-LEDs. By comparing

the light from the UV-LEDs to the constant energy

By

comparing the light from the UV-LEDs to the constant energy of the 207

Bi sources, it is possible to correct any fluctuations on the UV-LEDs.

After making those corrections, that light can be used to see if the

energy response of the SuperNEMO optical modules is drifting over time.

Tests with a top-bench version of this system at UT Austin outperformed

the 1% stability goal. The system has been installed and run

successfully at the site of the SuperNEMO detector. It will also begin

performing calibration runs some time in the year 2021.

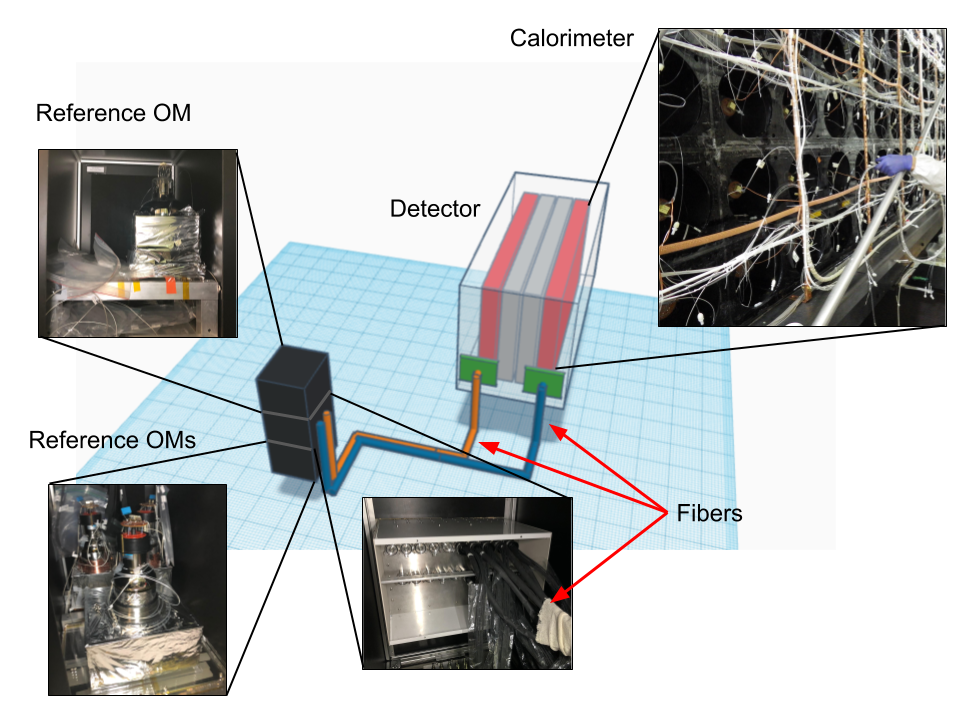

Schematic of the Light Injection and Monitoring System together with actual photos of the system as it is currently installed.